Some things are just built to last. Unfortunately in this age of instant gratification, those things are few and far between. Looking around your office or workspace, how many things do you see that were there a decade ago and still perform capably today?

Life, not to mention business, is in a constant state of evolution as people move forward with the times. Nobody wants to be left behind because they can’t keep up with the newest technology. But, what if you spend the resources on a new machine or product that actually holds its value down the road?

Ten years ago, the very first flatbed cutter to ever roll off of the manufacturing line at Summa was delivered to M.B. Trading Srl in Italy. That machine is still running strong today!

The F1612 improved M.B. Trading’s productivity and workflow so much, that they turned around and bought 2 more Summa flatbed systems.

M.B. Trading is a leading Italian printing, advertising, and graphics firm. Cutting-edge technology is the foundation for the products and solutions they provide. The purchase of Summa’s F1612 fit perfectly into their workflow because of its versatility and cutting precision. It helped the company in providing the perfect finishing and cutting solutions to their fleet graphics and building signage projects.

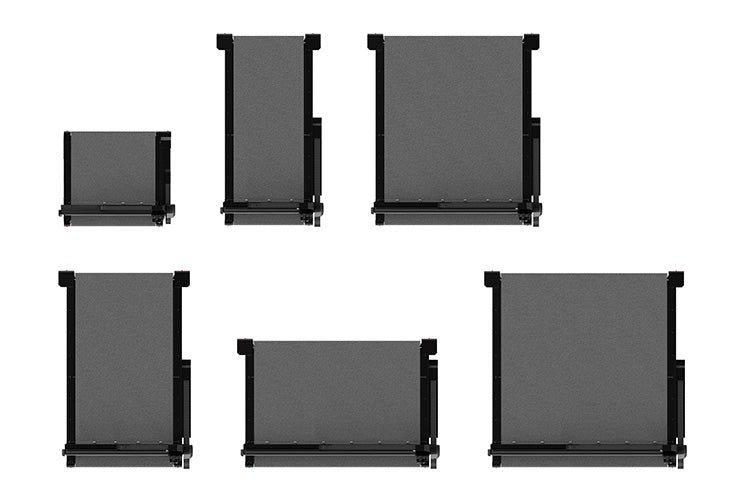

No other machine can match the versatility and adaptability of the Summa F-Series. Its heavy-duty construction and modular head allow you to install multiple tools simultaneously and work with a wide range of materials and media. Different cutting tools can be added at any time, making upgrades easy and cost-effective.

"No other machine can match the versatility and adaptability of the Summa F-Series."

Mr. Giampaolo Maffei, who is in charge of the digital equipment at M.B Trading, commented “a print provider who takes his job seriously should be creative, agile and bold if he wants to survive in the competitive world of print. Finishing, therefore, takes up an important part of the entire process, which should not be ignored in order to achieve a quality end-product. The implementation of the versatile Summa F1612 flatbed cutter into our machine fleet increased our production considerably. Especially, its ease of use is both a strength and advantage, which makes the machine an ideal addition to the printers in our production area. From 2010 up til now, our machine operators enjoy working with the F1612, which is why we decided to further streamline our workflow by purchasing another two F1612 flatbed cutters.“

Multiple Modules

The flatbeds’ multifunctional head holds up to three modules at a time. The central unit houses an LED pointer and an integrated camera system for fast and accurate contour cut mark recognition. The routing module is capable of milling most of the widely used solid boards in the graphics and signage industry, from hard foam PVC to acrylic and aluminum covered boards. The drag module allows you to make notations with pens or kiss cut a wide range of materials using a drag knife. The tangential module offers a vertical force of 10kg and can be outfit with a wide range of matching tools, all of which have a barcode ID to ensure automatic recognition and parameter settings. Last but definitely not least, is the rotary module option for textiles. The rotary module has a controlled decagonal, tangential knife capable of cutting all kinds of thin materials, fabrics, and textiles.

If you are thinking about investing in a flatbed cutter to improve your shop or operation’s throughput, make sure to talk to AirMark. We’ve been the leader in Summa F Series flatbed sales and installation for over a decade. We’d love to help deliver a system and increase your throughput in a way that we can all reflect on in another 10 years.

Call today to learn more about our Summa F Series Flatbed Cutters!